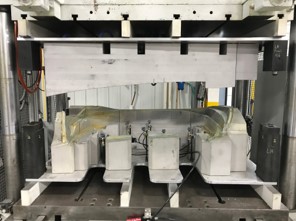

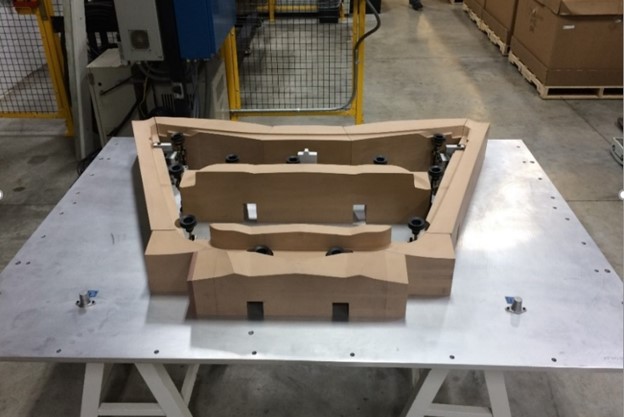

Our prototype bond fixtures are designed with math cut tooling nests, shimable datum locators, and vacuum cups. Each fixture cavity is machined with heat troughs in which allow heat to be applied evenly to the bond surfaces. The tooling is designed for quick changeover within our press. This allows us to manufacture prototype parts on production like tooling. For larger assemblies, bond fixtures can be designed to be placed within our walk-in oven. This creates another opportunity for bonding.